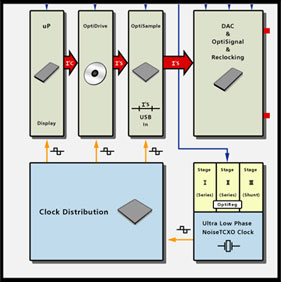

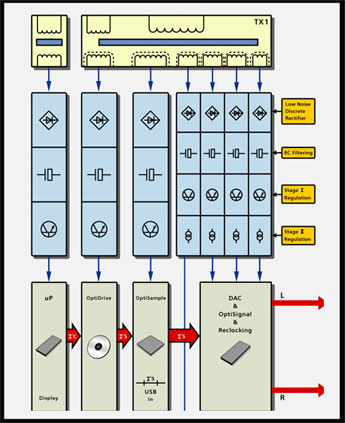

In contrast to the “classic era” methods employed in the manufacture of its transformers, AMR is proud of its patent-pending and groundbreaking OptiMains®power conditioning circuit which is at the envelope of audio mains design. The specially designed intelligent electrical mains control circuit is comprised of several key technologies that combined, immunise the power supply in AMR equipment from just about all noise problems associated with modern mains systems.

Noise problems arise from any number of sources. First, variations in mains voltage occur throughout the day due to load changes on the mains grid.

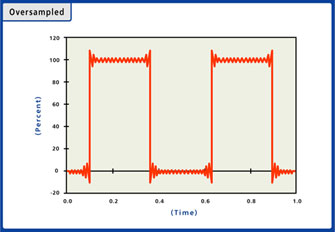

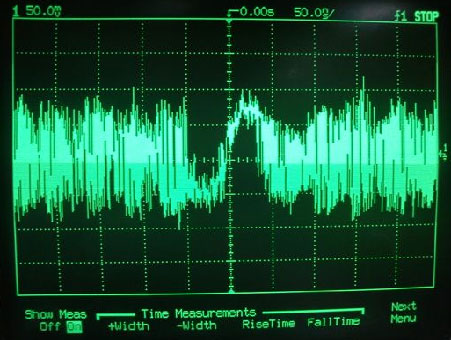

Second, and equally commonly, the mains waveform is heavily distorted and is subject to so-called flat-topping. Flat-topping additionally leads to offset voltages that can reduce the efficiency of transformer cores.

Third, there are numerous types of high frequency noise pick up such as those arising from radio waves.

Fourth, there is noise that has been deliberately introduced into the mains system such as from power line-based network communications. With this being the state of affairs in the most developed nations around the globe, it goes without saying that the quality of electricity available in many developing nations is even worse, much worse.

High frequency noise in the mains grid may “jump” through mains transformers, meaning the rectification and regulation is just as well as if they where not there, causing problems in downstream audio circuits. Voltage variations, especially over voltage will reduce the life span of all components. Thermionic electron valves are the worst affected, a 5% over voltage can cut the life span in half.

Flat-topping on the other hand results in low supply voltages (despite a normal rms voltmeter reading actually measuring the voltage as nominal!), with the result that the sound quality is not at its optimum. This is related also to the often observed “magic hour,” where late at night or in the early morning, with the load on the mains system at its lowest, the waveform at its best and with the least noise, sound is often much improved.

All these problems conspire to make designing a truly high performance audio device powered from the common mains grid a considerable challenge. The seemingly ideal solution of using batteries, be they rechargeable or not is fraught with a wide range of problems, not least the lack of convenience if you run out of battery power or charge in the middle of your favourite song. Hybrid approaches best called battery buffered have been implemented but seem to have enjoyed less sonic success than pure battery supplies.

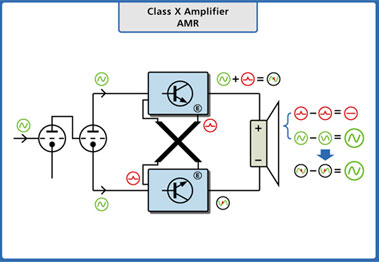

Thus AMR set out to once and for all resolve the mains powered problem. Attempts to use power factor corrected switched mode supplies, while initially promising, highly economical, lightweight and small, retained too many irresolvable problems to the detriment of sound quality. The eventual solution derived is what we call OptiMains®.

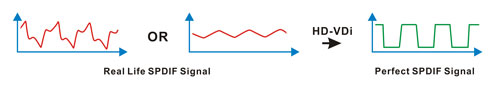

First, OptiMains®isolates the power supply from noise and direct current offset in the mains grid.

Second, OptiMains®detects and intelligently compensates for variations in the incoming mains, be they in the absolute voltage, due to flat topping or any other reasons. The result is to ensure that the internal electrical supply is unaffected by external fluctuations and is free of noise so that sound quality is therefore always optimised.

There are several striking advantages to OptiMains®.

First and most importantly, OptiMains®allows for downstream thermionic electron valve sections to have no regulation. This is a key design parameter the importance of which cannot be understated as it results in vastly better sonic qualities without the usual drawbacks. Further, the operation of all other parts of the audio circuit and/or digital circuits is tabilised at a defined and known point, ensuring that the sound quality always

remains optimised.

Second, the need for an external power-conditioning component is eliminated. In fact, most commercial power conditioners with the exception of so-called double conversion mains regulators do not address half the problems that OptiMains® does. Typical stand-alone power conditioners are not much better as they concentrate on noise reduction only.

Third, the lifespan and reliability of both thermionic electron valves and the equipment in general is greatly enhanced regardless of whatever the mains voltage.

Fourth, AMR equipment will work optimally without ANY modification on all known alternating current mains networks worldwide, be they nominally 100V/60Hz (some parts of Japan) or 240V/50Hz (UK).=